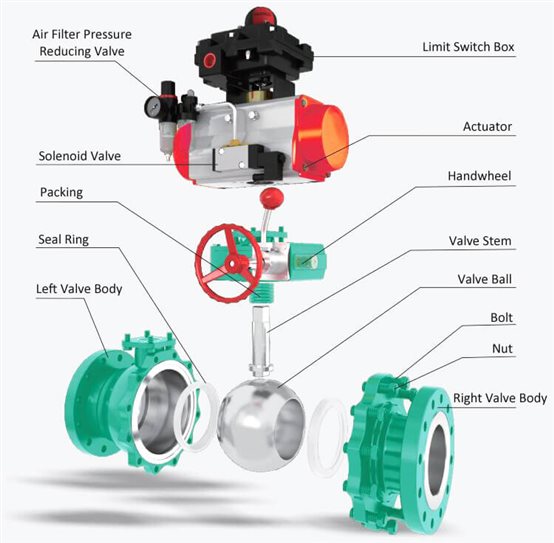

Pneumatic Operated On Off Ball Valve With Actuator

This pneumatic operated ball valve may be the top quality on off ball valve with pneumatic actuator.The pneumatic operated ball valve has got the characteristics of huge circulation capacity,compact structure,good sealing performance and lengthy service existence,which is economical, practical and low maintenance.

The on off ball valve with pneumatic actuator is broadly utilized in oil, chemical, gas, electrical power, metallurgy, food, pharmaceutical along with other applications where strict needs are needed. It is also put on water, steam, oil, liquefied gas, gas, gas along with other media. Additionally, fire-resistant and special hardening treatments could be selected based on customers’ needs.

Technical Parameters of Pneumatic Operated On Off Ball Valve With Actuator:

1.Nominal Pressure: 0.6~4.OMPa, 150LB,10K

2.Nominal Diameter: DN15-DN200 (1/2″ ?8″)

3.Connection Type: Flange connection,butt welding connection

4.Flow Characteristic:ON-OFF

5.Opening:90°

6.Valve Ball Action: the ball rotates clockwise and the valve closes;

7.Valve Seat Type :soft seat,metal seat(sealing surface hardening treatment);

8.Applicable Temperature:soft seat~ -20~+250℃;metal seat~-60?+ 450°C;

9.Leakage Class: soft seat~ANSI VI; metal seat~ANSI IV;

10.Design Standard: GB/T 12237,ASME B16.34;

11.Structure Length: GB/T12221,ASMEB16.10;

12.Test Standard: GB/T13927,API598;

13.Operation Type: manual,gear,pneumatic,electric;

14.Accessorirs: Solenoid valve,limit switch,air filter pressure reducing valve,

positioning valve, manual operating mechanism,etc;

15.Available Items

(1).Fireproof and antistatic design;

(2).Oil prohibition/water prohibition treatment;

(3).Copper prohibition treatment;

(4).Special treatment for valve ball surface;

(5).Special interface,equipped with pipes;

(6).Paint according to customer requirements;

(7).Application under vacuum conditions;

(8).Special testing requirements;

(9).Sandproof;

(10).Application in cold regions;

(11).Salt corrosion resistance.

Main Parts Materials of Pneumatic Operated Ball Valve:

Parts Name | Material |

Valve Body | WCB,CF8,CF8M,CF3,CF3M |

Valve Ball | 2Cr13,304,316,316+STL,etc. |

Seal Ring | PTFE,PPL,304,316,316+STL,etc. |

Stem | 2Cr13x 304,316,etc. |

Seat Spring | Inconel,etc. |

Seat Support Ring | 2Cr13,304,316 |

Gasket | stainless steel wrapped graphite |

Packing | V-PTFE,graphite |

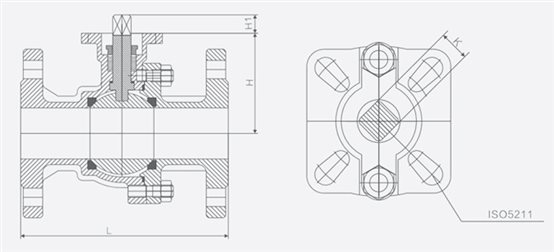

Dimensions of Pneumatic Operated On Off Ball Valve With Pneumatic Actuator:

DN(mm) | L(new) | L(old) | H | H1 | K | IS05211 |

15 | 130 | 130 | 50 | 10 | 9×9 | F04/F05 |

20 | 130 | 140 | 55 | 10 | 9×9 | F04/F05 |

25 | 140 | 150 | 68 | 12 | 11 x11 | F04/F05 |

32 | 165 | 165 | 75 | 12 | 11×11 | F04/F05 |

40 | 165 | 180 | 90 | 14 | 14×14 | F05/F07 |

50 | 203 | 200 | 98 | 14 | 14×14 | F05/F07 |

65 | 222 | 220 | 120 | 18 | 17×17 | F07/F10 |

80 | 241 | 250 | 135 | 18 | 17×17 | F07/F10 |

100 | 305 | 280 | 150 | 18 | 17×17 | F07/F10 |

125 | 356 | 320 | 165 | 25 | 22×22 | F10/F12 |

150 | 394 | 360 | 205 | 28 | 27×27 | F10/F12 |

200 | 457 | 400 | 260 | 28 | 27×27 | F12/F14 |

The Design Features of On Off Ball Valve With Pneumatic Actuator:

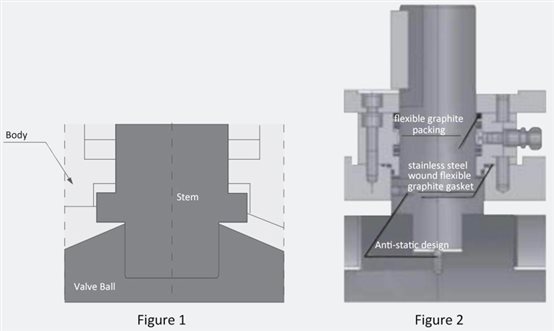

1.Valve stem anti-blowing structure design:

The valve stem adopts the anti-blowing structure design, and the valve stem with the big upper end and the small lower end is positioned under the upper end cover and the screw, so that the valve stem can not be blown out by the medium even if the valve chamber is abnormally boosted(check the Figure 1).

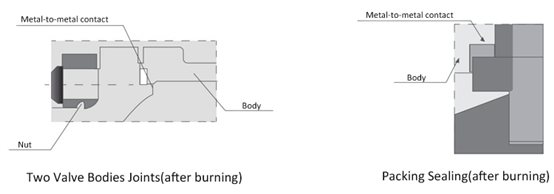

2.Anti-static design:

The pneumatic operated ball valve adopts an anti-static design to form a static passage through the ball, the valve stem and the valve body. Therefore, the electric power generated by the rubbing during the switching process between the ball and the valve seat is led to the ground through the valve body, thereby preventing the fire or explosion hazard which may be caused by the static spark(check the Figure 2).

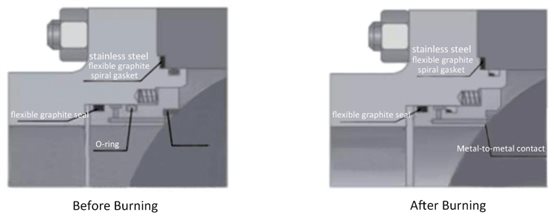

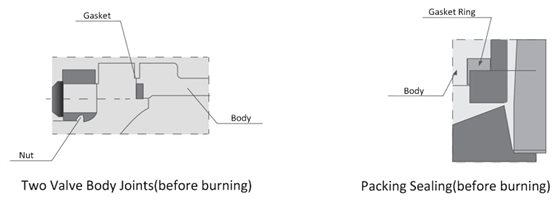

3.Fireproof structure design:

When a fire occurs, when the valve seat and seal made of non-metallic material are damaged at high temperature, the specially designed metal-to-metal auxiliary sealing structure effectively prevents a large amount of leakage of the medium.

4.The standard ISO-5211 connect plate is designed to facilitate the customer to change the operation mode at any time.

Product Characteristics of On Off Ball Valve with Pneumatic Actuator:

1. The valve is created by precision casting or forging,therefore the on off ball valve with pneumatic actuator has compact structure and delightful appearance. The fixed O-type ball valve ball and also the valve stem create a rotary motion. Once the ball is rotated, the valve seat is definitely in close contact and it has a powerful cutting capacity

2. The valve seat is preloaded with a round spring or perhaps a butterfly spring. It's automatic compensation, self-sealing and automatic pressure relief function within the valve cavity. It's appropriate for top temperature and pressure applications.

3.A number of sealing structures could be selected to guarantee the service existence and longevity of the pneumatic operated ball valve.The sealing type will come in soft and difficult seal, and also the sealing surface could be hardened for various operating conditions.

4.The automated pressure relief style of the valve cavity: once the temperature from the medium remaining within the valve body cavity increases and results in abnormal pressure rise, the security valve isn't needed, however the valve seat function can instantly relieve pressure, therefore increasing the safety from the the on off ball valve with pneumatic actuator.

5.Fireproof structure,anti-static structure, anti-blowing stem structure design could be selected. For that on off ball valve with pneumatic actuator,it adopts ISO 5211 actuator installation standard.

6.For the pneumatic operated ball valve,the stem length could be extended to match cryogenic applications.